Powering the Green Winter Olympics

2022 Jan 26

(26 January 2022, Nan Jing) Recently, Spokesperson Zhao Lijian announced at a regular press conference at the Ministry of Foreign Affairs that for the first time in history, the 26 venues in the three major competition areas of the Beijing Winter Olympic Games will be supplied with 100% green electricity.

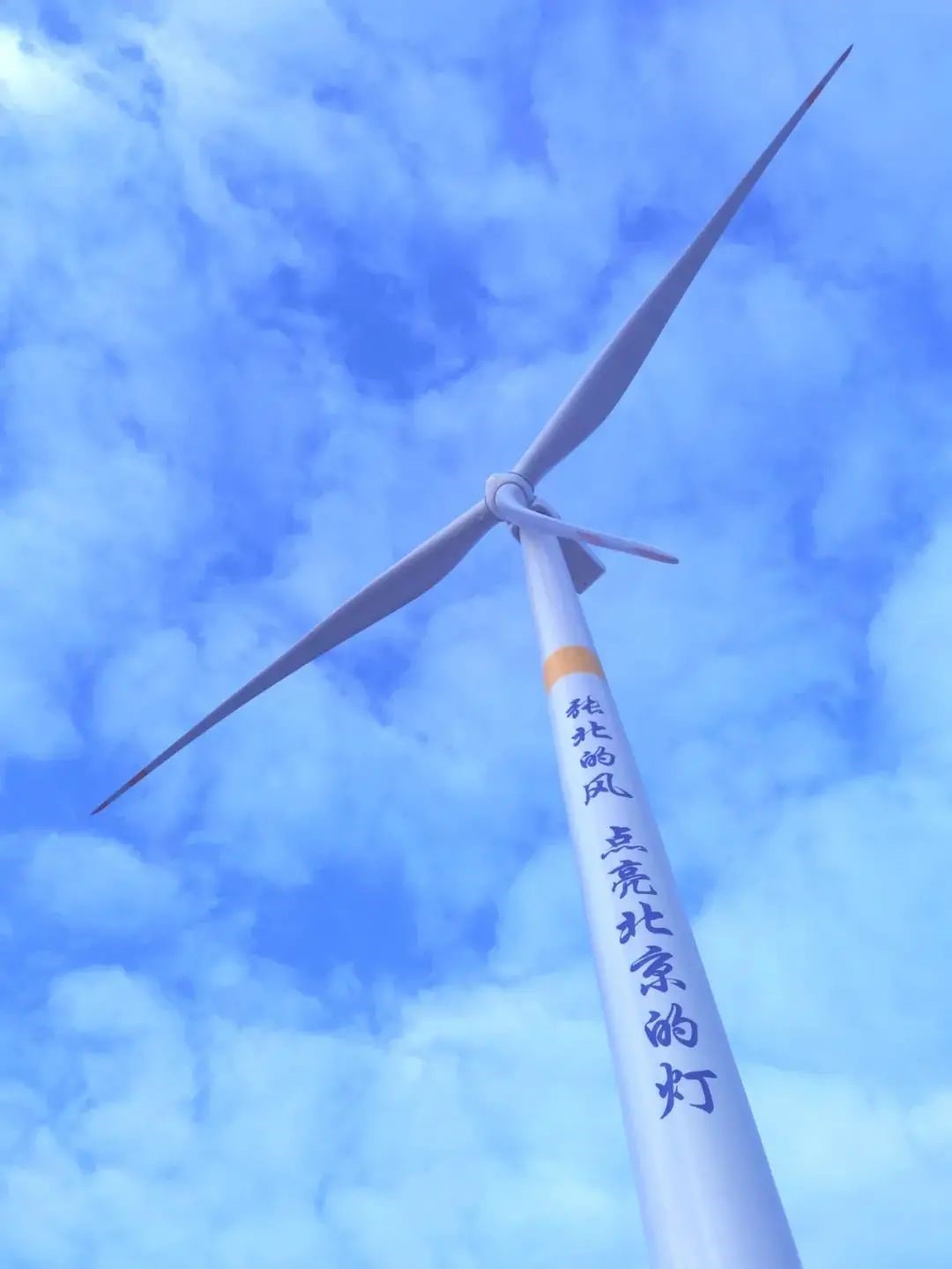

NGC, the green energy high-end equipment manufacturing segment company under Fullshare Holdings, independently developed the wind power main gearbox, which was applied to the Zhangbei Haojiaying 100,000 kW wind power project. As one of the clean energy demonstration projects supporting the Winter Olympics, the project will light up Beijing with “green power”.

Zhangbei’s wind lights up Beijing’s lights

China’s “Green Olympics” is not only to fulfil its “double carbon” commitment, but also to provide the world with China’s solutions, China’s wisdom and China’s contributions on handling the relationship between man and nature, development and conservation.

As the saying goes, “Wind in Zhangbei can blow from spring to winter”. The country has established the Zhangbei Renewable Energy Demonstration Project to convert the wind power in Zhangbei.

Source:Windey Co., Ltd.

Source:Windey Co., Ltd.

This series of gearboxes is NGC’s new generation StanGearTM standardised, modular and serialised platform product, which ensures that the gearbox power covers 3MW-4.5MW while the nacelle profile size of the turbine remains unchanged, significantly reducing the manufacturing cost per kWh for the customer.

The 3.6MW wind turbine main gearbox used in the Haojiaying project in Zhangbei is the first product of this platform, which perfectly meets the needs of users and is continuously delivering green electricity to Beijing.

Green power, green manufacturing

Considering the development trend of wind power market price competition, NGC fully considered the needs of domestic and foreign host manufacturers. Through continuous self-iteration and innovation, NGC integrates more than 90,000 gearboxes wind farm operation experience, using the “standardization, modularization, platform serialization” green design concept, the application of the latest reliability technology and developed a new generation of StanGearTM platform products.

This serialized platform products have wider environmental adaptability, higher reliability, higher transmission efficiency and higher torque density, and have been widely used in the main models of customers at home and abroad, creating more value for customers. It has greatly shortened the product iteration, effectively improved product reliability, and significantly reduced product manufacturing costs and life-cycle operation and maintenance costs.

With the coming opening of the Winter Olympics, NGC, as the backbone of the wind power industry, will carry out its corporate mission of “bring progress for human civilisation”, helping to follow “Green Winter Olympics” concept and letting the wind from Zhangbei constantly light up the lights in Beijing. At the same time, we will continue to drive high-quality development through innovation and contribute to accelerating the country’s energy transition and achieving the “double carbon” target as soon as possible.